Designing a tensile membrane basketball court requires balancing safety, functionality, comfort, and aesthetics.

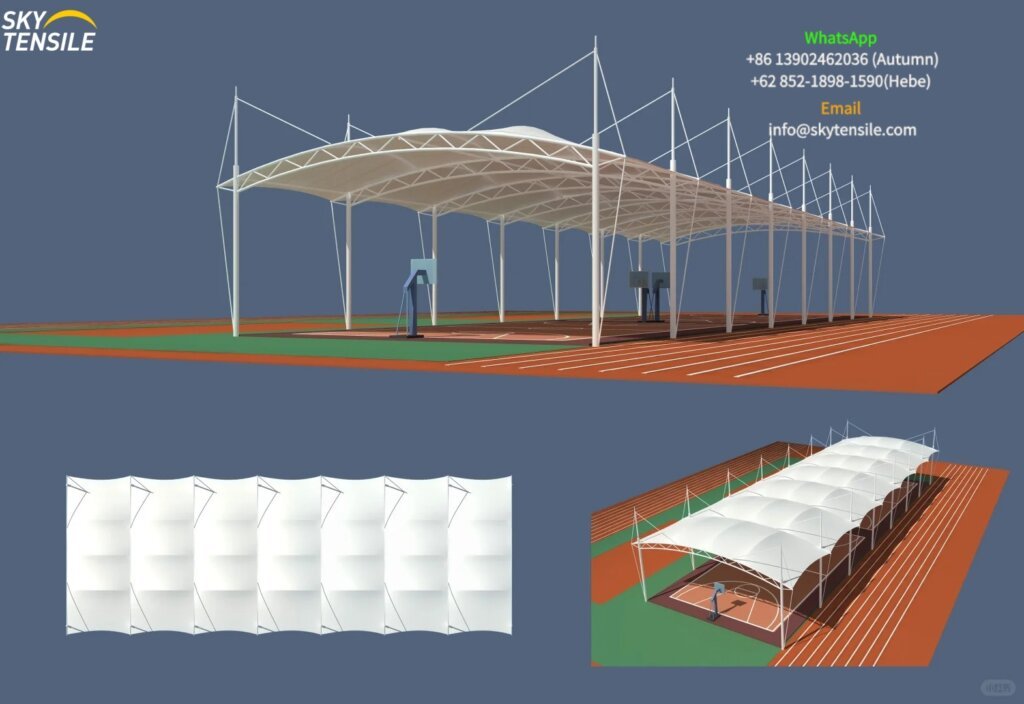

According to the Technical Specification for Membrane Structures (CECS 158:2015) and Steel Structure Design Code (GB 50017), the structure must be both stable and durable. The standard FIBA court size is 28m × 15m, with a minimum clear height of 7m (recommended 8m or higher for professional courts).

For materials, the two most common choices are PVC-coated polyester fabric and PTFE-coated fiberglass fabric:

- PVC membrane – cost-effective, easy to install, available in various colors, ideal for community or training courts.

- PTFE membrane – highly durable, self-cleaning, and provides soft natural light, perfect for professional or long-term use.

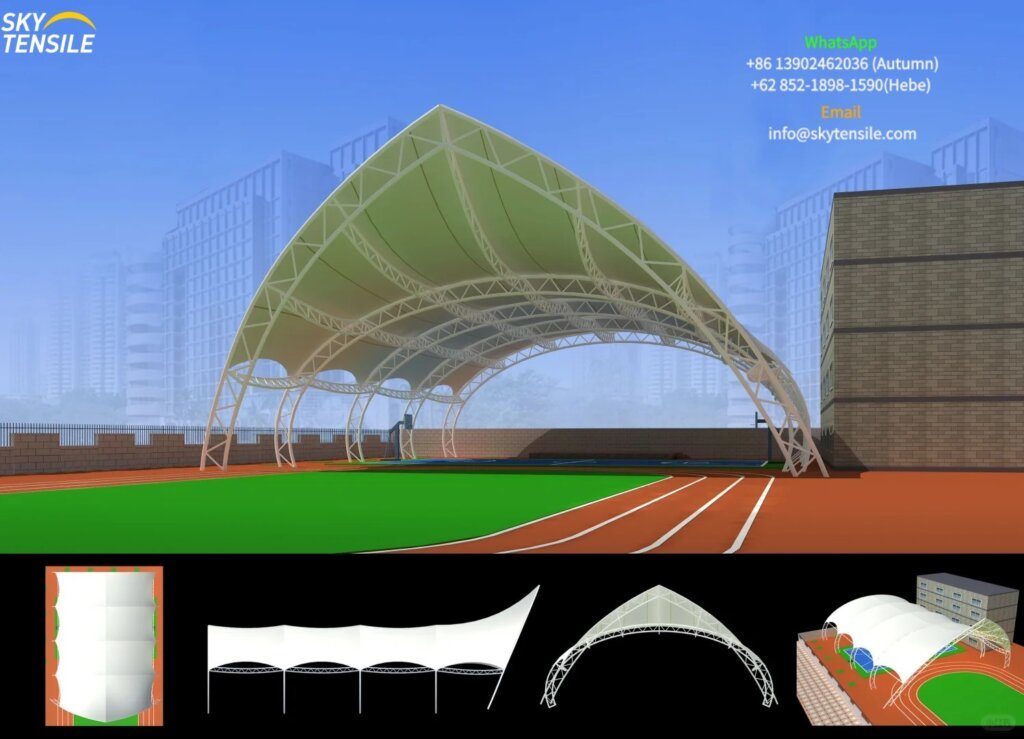

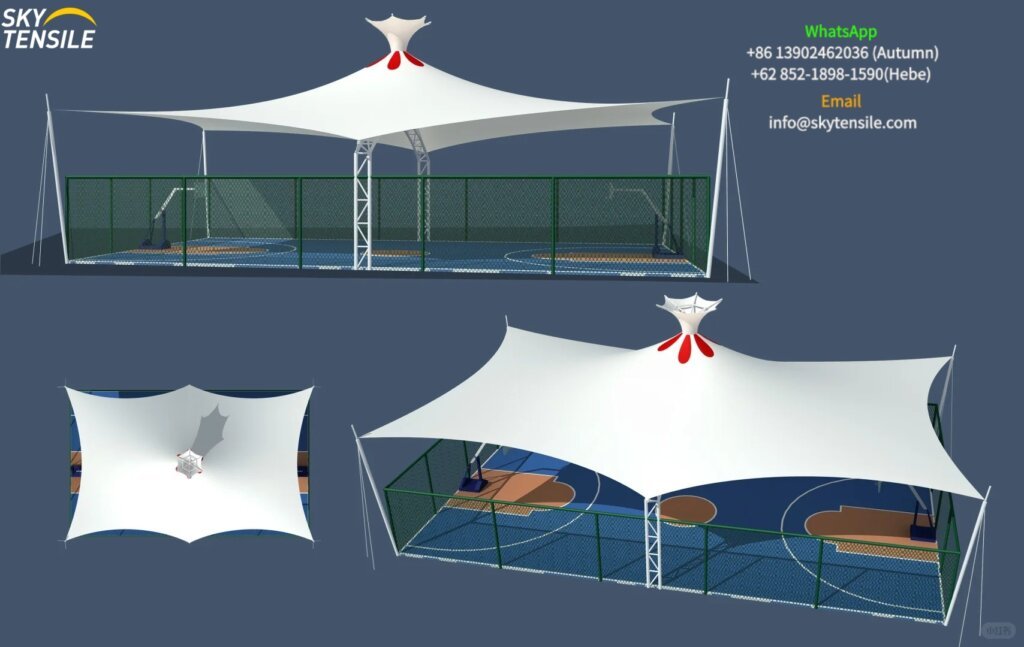

The form-finding design can take various shapes such as saddle, cone, or arch, with a minimum slope of 10% for drainage. Supporting structures often use steel or cable-membrane systems, and all joints must ensure safe and clear load transfer. Wind, snow, and pre-tension loads should be analyzed using professional software like WinTess or EASY for nonlinear structural stability.

Lighting design is another key element. Training courts should provide ≥300 lux, and competition courts ≥500 lux, with a color rendering index (Ra) ≥80. The translucent nature of membrane materials offers excellent natural lighting, reducing energy consumption. Proper ventilation design can also enhance air circulation.

In short, a tensile membrane basketball court combines lightweight beauty, structural flexibility, and energy efficiency, making it an ideal solution for modern sports facilities. With smart design and material selection, it provides both safety and comfort while delivering a visually striking architectural effect.