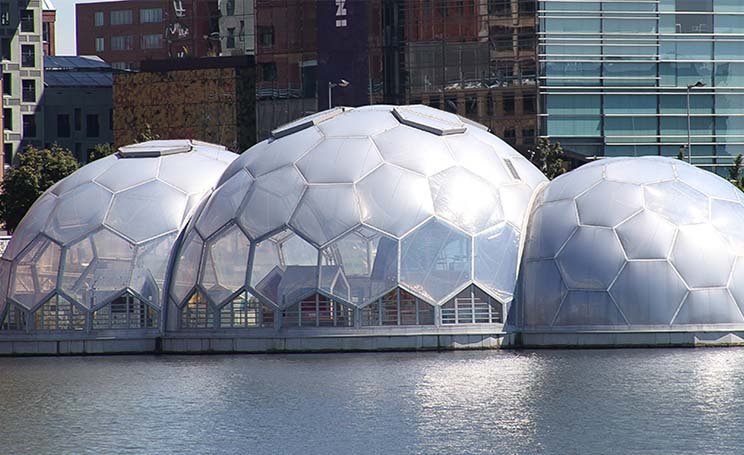

A membrane structure is a part or the entirety of a building or construction composed of a membrane surface and supporting structure. Membrane structures integrate architecture, structural engineering, materials science, and computer technology. With over 40 years of development internationally, many unique and aesthetically pleasing membrane structures have been built worldwide, offering excellent functionality. There are now specialized manufacturers and companies dedicated to the fabrication and installation of membrane structures, along with established standards and guidelines.

Membrane Material Classification

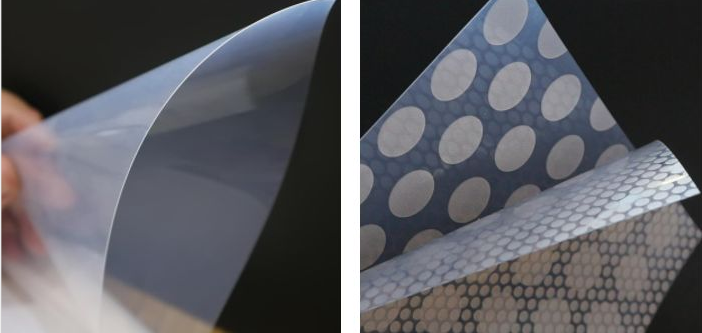

Membrane materials are composite materials made of high-strength fabric substrates coated with polymers, extensively used in membrane structures. Based on the fabric substrates and coatings used, membrane materials are classified into various types:

1.By Material and Construction:

- Type G: Coated fabrics with a continuous polymer layer on a fiberglass fabric substrate. These materials offer excellent heat and weather resistance, suitable for structures requiring high strength and durability.

- Type P: Coated fabrics with a continuous polymer layer and an additional surface layer on a polyester fabric substrate. Type P materials provide good flexibility and elasticity, ideal for applications needing tear resistance and flexibility.

- Type EP: Coated fabrics with a fluoropolymer layer on an expanded PTFE (polytetrafluoroethylene) fabric base. EP materials offer superior chemical resistance and self-cleaning properties, making them ideal for high-end architectural projects.

- Type E: ETFE (ethylene-tetrafluoroethylene) films made from copolymers of ethylene and tetrafluoroethylene. ETFE is lightweight, transparent, and highly weather-resistant, commonly used in structures requiring extensive natural lighting.

2.By Substrate and Coating:

- Type A: Fiberglass substrate coated with PTFE. This combination provides exceptional heat resistance, chemical resistance, and self-cleaning properties, suitable for structures demanding high durability and weatherability.

- Type B: Fiberglass substrate coated with PVC (polyvinyl chloride) or fluororesin. Type B materials are cost-effective, making them suitable for general building structures and temporary installations.

- Type C: Substrates made from polyester, polyvinyl alcohol, or polyamide fibers, coated with neoprene or PVC. These materials offer good flexibility and mechanical strength, ideal for applications requiring high tensile and tear strength.

3.Other Common Combinations:

- PTFE-coated polyester fabric: Combines the weather resistance of PTFE with the flexibility of polyester, widely used in mid to high-end architectural membrane structures.

- PVC-coated polyester fabric: A common choice for economical membrane structures, suitable for temporary buildings or quick installation projects.

The selection of membrane materials is typically based on specific architectural requirements, including durability, self-cleaning ability, light transmission, heat weldability, and mechanical properties. Different combinations of substrates and coatings provide varying performance levels to meet diverse architectural needs.