Tensile Membrane Material

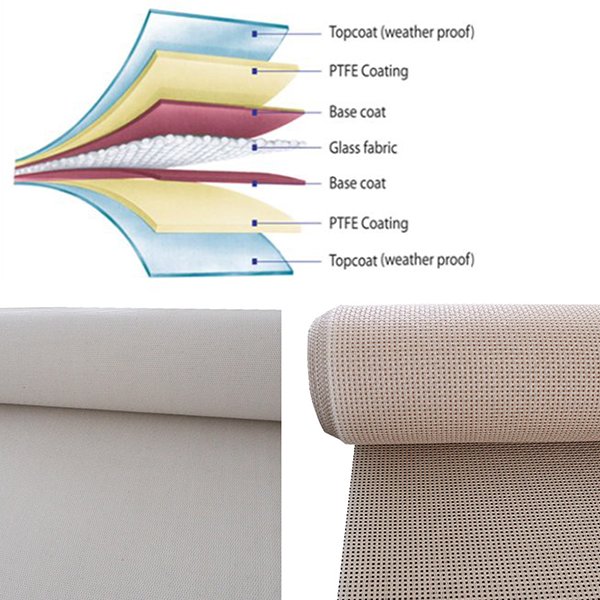

PTFE membrane material is a composite made of fiberglass with a PTFE (polytetrafluoroethylene) coating. PTFE absorbs light, especially UV rays, and gets whiter with exposure (the more sun, the whiter it gets).

Applications:

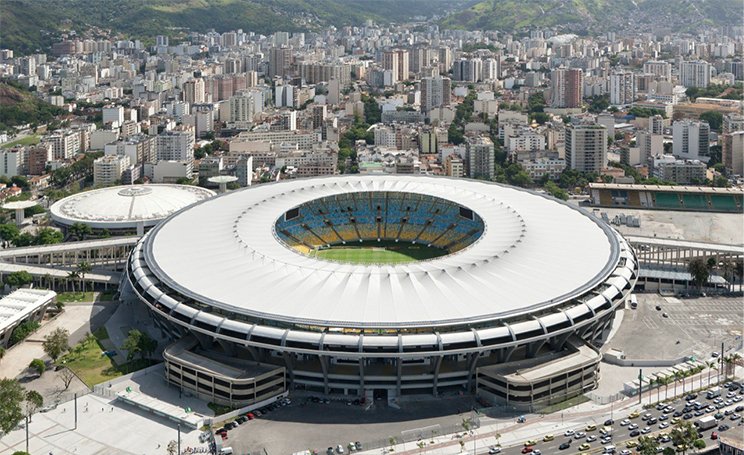

Commonly used in large public buildings and commercial plazas, like roofs or facades of airports, train stations, stadiums, ventilated facade screens and urban landscapes.

Main Benefits:

Lightweight: Much lighter than traditional materials, less than 1.5 kg per square meter.

Strong: Fiberglass is the strongest textile, even stronger than steel wire of the same diameter.

Flexible: Can be stretched into dynamic curves, creating complex shapes.

Light-Transmitting: Provides soft, diffused light through its surfaces.

Self-Cleaning: Needs minimal cleaning; rain easily washes away dirt due to its non-stick surface.

Inert Surface: Resists harsh conditions like mold and acid rain.

Weldable: Can be welded into large, strong canopies.

Long-Lasting: Almost no degradation, lasts at least 25 years, considered a permanent material.

Fire Resistant: Rated B1, with some parts reaching A2.